|

Search the Noteworthy Practices database A Life-Saving and Cost-Effective Solution For An Environmentally Sensitive LocationOriginal publication: Case Study: Northern California US 199-Del Norte County; FHWA-SA-15-055; 2015 (PDF, 2.3MB)Publication Year: 2015

Northern California, near the Oregon State line is home to the Redwood National and State Parks, which span over 200 square miles and are some of the most environmentally diverse areas in the United States. Accordingly, transportation construction projects that disturb existing conditions within the parks' limits are subject to stringent environmental restrictions and long permitting processes. BackgroundOver the last decade, a horizontal curve within the parks' limits experienced a high frequency of wet crashes. This curve, shown in Figure 1, is located on US 199, a two-lane, rural highway in Del Norte County, approximately one mile east of the South Fork Road intersection. It has a radius of 280 ft. and an advisory speed of 30 miles per hour (mph). Between 2006 and 2009, this site experienced 26 wet crashes and exhibited total and severe (fatal + injury) crash rates that were 7.3 and 4.3 times, respectively, greater than the statewide average for similar facilities. Crash types included run off road, head-on, and opposite direction sideswipe.

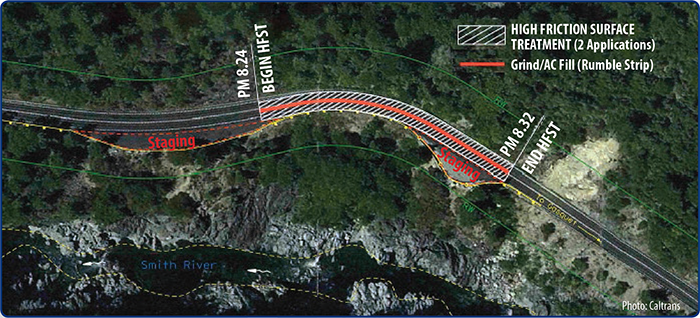

Figure 1. US 199 in Del Norte County Caltrans previously installed several low-cost safety countermeasures at the site including center line rumble strips, speed warning signs, double stacked chevron signs, and one inch open grade asphalt concrete (OGAC) overlay. Yet, these treatments did not lead to the crash reductions Caltrans desired. They began to consider larger scale countermeasures, specifically roadway realignment. However, the realignment process would require a lengthy environmental review and mitigation of wetland impacts before the improvement could begin reducing crashes. As an alternative to realigning this curve, Caltrans began to investigate a High Friction Surface Treatment (HFST) and looked to other States for guidance and successes. Factors Affecting the Final Decision

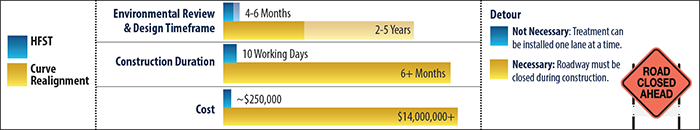

Figure 2. Threatened Species Most critical for Caltrans at this location was mitigating environmental impacts. US 199 parallels the Smith River, the most pristine and environmentally sensitive river in California, protected by a full spectrum of environmental entities and regulations. The surrounding area sustains California's most diverse ecology, including the Marbled Murrelet and Northern Spotted Owl, as shown in Figure 2, both threatened species protected by the Federal Endangered Species Act. The area also contains over 400 separate species of plant life and a large number of active, very small wet lands. Due to endangered species and water quality concerns, a roadway realignment project within the parks' limits would require Caltrans to spend six months acquiring environmental permits. Further, the North Coast Regional Water Quality Control Board requires Caltrans to mitigate construction effects upon the wetlands, even when impacts are only a few square feet. Wetland and impervious area mitigation ratios can range from 1:1 to 1:4 depending on several factors. If the replacement is to take place within another roadway project, it could be years before Caltrans is able to begin work on the initial project as crashes continue to occur. In contrast, HFST environmental impact and associated review is minimal and requires only a Categorical Exemption/Exclusion (CE/CE) document. HFST's nominal effect on the surrounding environment is due to the treatment's application between existing pavement edges, resulting in no net increase of impervious areas within the Park’s limits. In addition, any geometric improvement that involves construction incurs time restrictions (i.e., environmental windows) aimed at not disturbing wildlife. This would force Caltrans to either perform large-scale construction projects in stages or to use an accelerated/restricted schedule, both of which have significant effects upon the project. Conversely, HFST has the distinct advantage of an installation time period of just 10 working days. HFST could be implemented quickly compared to alternatives, satisfying Caltrans’ environmental concern, construction time schedule, and window of opportunity.Lastly, a feasible detour route for the realignment is not available because a network of local county roads that connects the lower and upper portions of the county does not exist. A detour around US 199 could take longer than 8 hours, which is estimated to cost upwards of $450 million a year in associated economic losses. HFST can be installed one lane at a time and therefore does not require a detour at any point during construction. Table 1 summarizes and compares each countermeasure's environmental review and design time frames, construction duration, costs, and need for a detour.

Table 1. Comparison of Factors between HFST and Curve Realignment on US 199 Selecting HFSTIn summer 2012, Caltrans opted for the simpler, but still very effective, alternative. They installed 850 ft. of HFST at this horizontal curve on US 199, shown in Figure 3. The treatment consisted of a double layer of epoxy-resin binder with calcined bauxite aggregate, which filled in the surface voids from the previously installed OGAC and added protection against water penetration. With a peak hour volume of approximately 600 vehicles per hour (vph), Caltrans estimated only a 5 minute travel time delay during active construction. Caltrans is unaware of any crashes at this location since the HFST implementation. To date, 139 sites on State maintained roadways in California have received HFST or will receive the treatment in the near future. Caltrans continually encourages and tries to educate its districts about the benefits of HFST. The agency believes that HFST is one of the best tools in its toolkit for challenging curves and should be the primary “go-to” friction enhancing countermeasure, even before OGAC.

Figure 3. US 199 HFST Application Area What criteria does Caltrans use to install HFST?Caltrans believes HFST is an appropriate safety countermeasure for both wet and dry locations, high and low volume roadways, and tangents as well as curves. It is effective at mitigating crashes involving large changes in speeds (acceleration/deceleration), low skid numbers, tight horizontal curves, and roadway departure. As a result, Caltrans has implemented HFST on a large variety of locations including horizontal curves, bridges, wet crash locations, signalized intersections, on- and off-ramps, and short freeway segments. Are there any locations where HFST is not appropriate?Caltrans does not apply HFST in cold/icy locations where heavy trucks frequently use chains in winter, as the chains significantly decrease HFST's lifespan. Further, in long tangent sections with intense rainfall, OGAC is preferred. ContactsJoseph Cheung Frank Julian Publication Year: 2015 |